Results 1 to 19 of 19

Thread: Oil in discharge line

-

28-10-2008, 07:25 AM #1

Oil in discharge line

Hi all

I have a Copeland DMHR705 compressor, there is loads of oil in the compressor discharge line.

The compressor is operating on R22, there is no oil seperator, oil return system, there are no suction line driers, the oil level in the compressor sump is correct (approx 3/4 full) etc.

The system runs with a remote condenser, the discharge line has a non return / check valve in it.

The discharge to condenser line has a vertical lift of 6mtrs.

I have done a drop test on the check valve and the pressure dropped to suction pressure quickly and held with no more pressure increase.

-

28-10-2008, 09:12 AM #2

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

-

28-10-2008, 03:14 PM #3

Re: Oil in discharge line

My first question is,

Is there a problem with the system?

Was it working OK or did it develop a fault?

I ask because there will be a lot of oil in the pipe because it will always

run back down the pipe on shut down, unless like the Nike man says it

has traps in the line.

Explain the working of the one way valve again, do you think it is passing

or do you think it is working ok?

Cheers taz.

.

-

28-10-2008, 03:42 PM #4

Re: Oil in discharge line

Please tell use the temperature of the place being refrigerated,as r22 used on a freezer at -20 the oil does not mix and would require an oil separator.Anon return is not normally used on single evaporators but on multiples at different temperatures.I agree that in this case you need a trap and riser.

-

28-10-2008, 10:00 PM #5

Re: Oil in discharge line

Hello Chillyblue.

The oil level of 3/4 glass is this when it is at a standstill or when it is running.

At a standstill the level could be slightly high!

When running it is definitely high!!!

If it is the later then that is the likely cause of your excessive oil carry over.

If not then prolonged periods of the compressor running in low load conditions could be the cause?

Mechanical wear is another.

A few simple checks can eliminate most of the causes.

Let us know how you get on!

Grizzly

-

29-10-2008, 12:10 AM #6

Re: Oil in discharge line

Dear chillyblue

The good first starting for the system should be with perfectly cleaning pipes from oil and the oil level should be less then the centre line with no load ( if the compressor in good condition) and the unit running in good performance if the installation as Engineer NIKE123 show u so that u should clean the system and test the compressor alone then the operation condition will be better.

Noori

-

29-10-2008, 07:54 AM #7

Re: Oil in discharge line

Thanks all in advance.

Just to answer a few questions,

Casstrig, room operating temp 3 deg C

Nike No there are no traps in the riser (this system has been installed for 12 years, i think you are exactly right and is good practice, but my client is going to find it odd that i need to alter the pipe-work.)

Grizzly Oil level is 3/4 when running. The level is as the sticker indicating correct oil level by manufacturer.

TAZ The history of the machine, It has worked fine for years but it did have a valve plate change about 4 years ago, the fault i was called to was due to the system tripping on hp, when checked i found the hp was only getting very high at the compressor, i'm assuming it was due to the logged oil line (causing hydrolicing/ and high start up pressures). To see if the one way valve in the discharge line works ok i fitted my gauges to the hp side and the lp side, pumped the system down so i had approx 2 psi on the suction side, i then released the hp gas through my gauges into the lp side, the lp went up and the hp dropped and balanced with the lp side quite quickly. If the one way valve was leaking the pressure would take a very long time to balance as it would also be emptying the condenser, reciever,liquid line etc. So i believe it is working ok (but i could be sticking at times , how would you know)

If the one way valve and the discharge valves on the compressor are fine (No pressure drop) would oil be able to get back through (if gas can't)?????????????????

Are the traps in the riser there to assist in oil flow only or there to also prevent flow back?????

I'm returning to site on Friday.

Cheers CB

-

29-10-2008, 09:05 AM #8

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Oil in discharge line

Where is placed non-return valve?

At the inlet of condenser would be OK. It purpose is to replace inverted trap at top of riser and that is to prevent liquid refrigerant from flowing backwards into the compressor during off cycles.

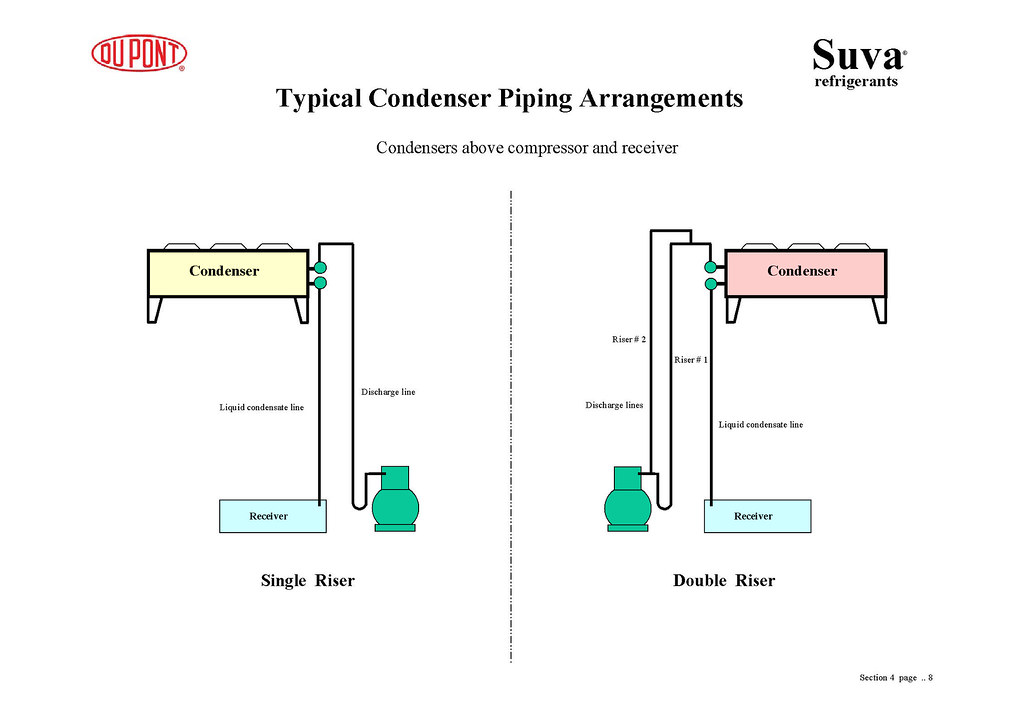

If it is somewhere else, you have bad design problem. Also with conjunction with non-return valve you should have oil trap at the bottom of vertical line and slope toward that trap from compressor discharge.

For your application double risers are not necessary.

You also could downsize discharge riser (vertical portion) pipe for one pipe size to provide better oil management.

-

29-10-2008, 09:12 AM #9

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Oil in discharge line

All horizontal lines should have slope in direction of refrigerant flow.

-

29-10-2008, 10:10 AM #10

Re: Oil in discharge line

Chillyblue

Many thanks for your prompt and concise response.

As it gives a better picture off the problem.

Which allows us all to voice an opinion.

I will check through my records and get back to you, but it does not make sense to me. To have an operating oil level that high!

It is quite normal to have oil on the discharge side of a compressor.

whereas I have to disagree with what

Nike says about the placement of the non return valve. (sorry no criticism meant)

Normally you place the non-return valve close to the compressor.

Especially where long pipe runs to the condenser are concerned.

If you don't when the compressor stops any condensed discharge gases.

Which can revert to liquid form if the comp is off for long enough.

Could run back to the compressor and cause a hydraulic lock upon start-up.

I assume this compressor is not to large so it is relying upon its own ability to return the oil through the system.

Therefore One way of confirming whether the oil level was to high.

Would be to drop the set-point.

So that the comp runs fully loaded and see if any oil returns back to the compressor

I am not sure whether you still have the Hp problem or have resolved it?

If it still exists.

I have yet to come across oil in the discharge line causing this.

The first thing I would normally suspect would be worn discharge valves.

You tell us that you have high pressure at the comp.

In fact what you describe is the classic symptoms of worn discharge valves.

The fact that the pressures at the comp equalise would prove the non return valve is sound.

But the pressures equalising "quite quickly" across the comp tell a different story.

Coupled with the oil in the discharge line speaks volumes.

Silly I know but have you confirmed this with gauges (system or your own).

It is not unusual for hp switches to fail.

I hope this helps some?

Good luck Grizzly

-

29-10-2008, 10:32 AM #11

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Oil in discharge line

Good argumented discussion cannot be criticism.

This is what I base my recommendation here and it is from MCQuay refrigerant piping design guide (application guide AG 31-011)

Discharge Line Piping Details

Discharge lines carry both refrigerant vapor and oil. Since refrigerant may condense during the off

cycle, the piping should be designed to avoid liquid refrigerant and oil from flowing back into the

compressor. Traps can be added to the bottom of risers to catch oil and condensed refrigerant during

off cycles, before it flows backward into the compressor. Intermediate traps in the risers are

unnecessary in a properly sized riser as they increase the pressure drop. Discharge lines should be

pitched 1/8 inch per foot (10.4 mm/m) in the direction of refrigerant flow towards the condenser.

Whenever a condenser is located above the compressor, an inverted trap or check valve should be

installed at the condenser inlet to prevent liquid refrigerant from flowing backwards into the

compressor during off cycles.

-

29-10-2008, 10:52 AM #12

Re: Oil in discharge line

Your absolved my friend.

I stand corrected!

2 problems with that design.

1) Most plant rooms don't lend themselves to perfect pipework runs.

2) More importantly though the length of the pipework (and it's pipe size)between the compressor can hold a considerable amount of refrigerant.

So in most cases it's just easier to fit 1 at the comp / oil separator end.

If there is more than 1 compressor on a shared discharge header. You do need the individual non-return valves at the compressor

But thanks for the useful reference keep up the good work.

And lets hope Chillyblue can solve his problem.

Grizzly

PS had 1 yesterday repaired leaking fitting on the oil separator. opened the discharge line feeding it.

Which bypassed a leaking non-return valve and blew out the compressors bursting disk.

Which I then had to replace, before I could reinstate the system.

As they say "i was not a happy chap!"Last edited by Grizzly; 29-10-2008 at 10:58 AM.

-

29-10-2008, 08:59 PM #13

Re: Oil in discharge line

Hi Nike/grizzly

The check valve is at the compressor.

The compressor has no cappacity control so runs fully loaded at all times.

I thought exactly what you thought Grizzly that it had worn discharge valves and have replaced the valve plate, i am also going to check the condenser fan staging as when the system stabalized the hp was quite low, this low pressure could also reduce the velocity up the discharge line which is possibly why (the oil is not getting up the pipe as easy and possibly collecting/falling back) the problem has shown it's self now the ambient temperatures are lower than they were in the summer.

Just to clarify Grizzly the compressor valves are now holding fine. I used my gauges to dump the discharge pressure into the suction, (the check valve is only about 2ft away from the compressor, so i new if the check valve was holding it would equalize quick, cause it is only a short section of discharge gas to loose), it did not leak through the compressor valves.

Cheers CB

-

29-10-2008, 09:12 PM #14

Re: Oil in discharge line

Well CB

I am beginning to wonder who is teaching who here.

It seems as if you have got all bases covered here and yes I also agree with your next move.

As you say the poor gas volumetric flow is 1 of very few options left.

All the same thanks for the update

Intriguing isn't it?

Grizzly

-

29-10-2008, 09:19 PM #15

Re: Oil in discharge line

Thanks for the compliment Grizzly.

i'm always prepared to learn, incase i am making mistakes!! i also like to get my actions/thoughts confirmed.

I'll let you know what happens on Friday.

Cheers CB

-

29-10-2008, 09:34 PM #16

-

29-10-2008, 10:58 PM #17

Re: Oil in discharge line

Credit where credit due mate

.

.

Does the thing run Ok or is there a recurring fault on the system?

I ask because if it is working and has worked for years then why not just let it run as is.

1 X valve plate over the years is not unusual.

The oil will run down the discharge on shut down without the traps but if it has not been a problem so far then I would be tempted to leave it be.

You have proved all to be fine, once your happy about the cond settings.

All the best taz

.Last edited by taz24; 29-10-2008 at 11:07 PM.

-

30-10-2008, 01:14 AM #18

Re: Oil in discharge line

If the compressor has no capacity control, the mass flow would remain fairly constant. If the discharge pressure was lower than normal, the velocity in the discharge line would increase. Originally Posted by chillyblue

Originally Posted by chillyblue

The reason for this is: as the gas pressure is reduced/lowered the vapor volume increase. This means the actual line velocity would increase because:

mass flow X specific volume = volume flow, therefore:

volume flow / pipe diameter = velocity

so,

high volume flow = higher velocity with the same size discharge pipeIf all else fails, ask for help.

-

30-10-2008, 06:52 AM #19

Re: Oil in discharge line

Thanks TAZ

i'll post the outcome and it's performance.

The reasons for my concerns were often people change things but don't actually find the real cause of why it originally failed, i.e. compressors, i was just making sure i had covered all the angles so another failure wasn't imminent, like you said, i think i have apart from re-piping it all.

US Iceman.

OK that puts a different light on the subject, i'll check anyway.

Thanks all

CB

Similar Threads

-

Superheat and Subcooling

By Chunk in forum FundamentalsReplies: 42Last Post: 15-01-2011, 01:24 AM -

punctured discharge line

By lksher02 in forum Technical DiscussionsReplies: 3Last Post: 05-08-2007, 11:41 PM -

Oil Leak in NH3 Discharge Line Flange

By NH3LVR in forum IndustrialReplies: 9Last Post: 26-05-2007, 09:15 PM -

Exploded discharge line

By Peter_1 in forum IndustrialReplies: 1Last Post: 05-05-2004, 09:47 PM