Results 1 to 5 of 5

Thread: samsung dvm new install

-

25-06-2010, 06:00 AM #1

samsung dvm new install

gday guys,

like a lot of others i found this site whilst trawling the net for answers and have already spent substantial time reading previous threads!

i am currently installing a samsung dvm +3 system to a new office building under construction here in western australia.

the system comprises two rvxvht100ge (10hp) outdoor units with 16 neo forte wall splits and 1 mini cassette.

i have vacced the system out multiple times (about 10 times now) using javac (160litre) and cps (140litre) vac pumps with a pair of cps vg200 digital vacrometers. each time the system has had 15+hr evacuation and has had huge amounts of nitrogen put through it for pressure testing so its most certainly dry.

samsung have advised i need to achieve a vacuum that holds at 500micron for 1hr after switching off the vac pump.

i havent been able to achieve this level so far to date, the vacrometer rises over 1000micron at the +1hr mark so i presume there is a leak in the system somewhere.

i have charged a small amount of refrigerant as a trace gas and pumped up the pressure to 400psi with dry nitrogen for leak detecting.

i have a javac d-tek electronic leak detector and have methodically checked every single pipe branch weld, every individual eev flares and the flares on each indoor unit.

i have found a few very small leaks which appear to be as a result of physical pressure on the flare nuts at the indoor units caused by the piping behind the unit.

the flares themselves were all ok, but i cut them off and redid them all anyway and then retested them all ok.

the most likely place for a leak now, as i can see it, is either on one of the indoor coils (factory side leak).

my next avenue is to cut the pipes in the ceiling space as they branch off to different parts of the building and vac and test each of the 4 sections individually.

cutting 1+1/8" pipe and then having to reconnect it later where it sits on the ceiling doesnt excite me.

for those of you who have had very small leaks like this on vrv/vrf systems before, how have you tracked the leak?

many thanks,

rob.

-

25-06-2010, 09:32 AM #2

Re: samsung dvm new install

Without stating the obvious

When you stopped the vac pump did you isolate it from the system?

Have you checked your gauge fittings.

500 microns to 1000 microns is less than 1/2 a torr rise

and the system needs to be down less than 2 torr / 2000 microns.

If you leave it longer tan an hour does the micron reading go high than a 1000??

Cheers taz

.

-

25-06-2010, 10:49 PM #3

Re: samsung dvm new install

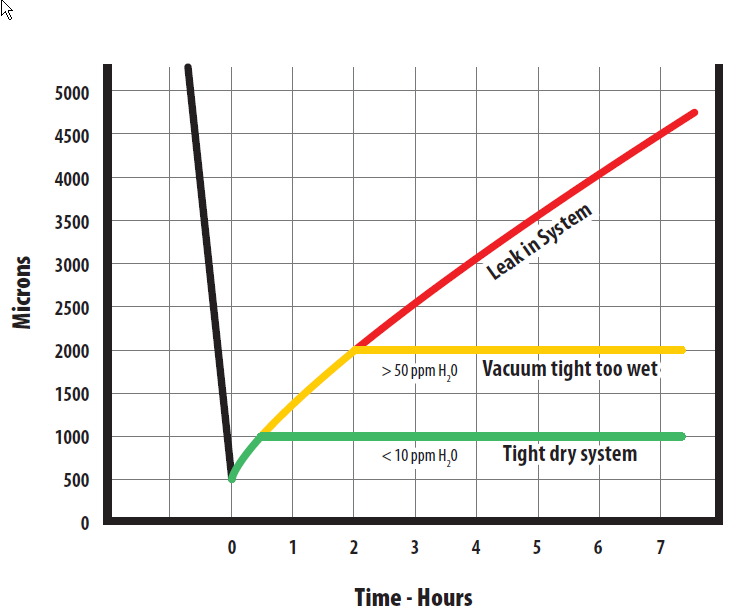

May be useful

Brian - Newton Abbot, Devon, UK

Brian - Newton Abbot, Devon, UK

Retired March 2015

-

30-06-2010, 12:27 AM #4

Re: samsung dvm new install

hi , you seam to be rushing through the pressure test , to get to the vac out, but before you can sucsessfully vac out , you must be sure you have no leaks, one job at a time , correctly done-

Last edited by sedgy; 30-06-2010 at 12:29 AM. Reason: usual pizzpoor spilling hic

-

04-07-2010, 09:29 AM #5

Re: samsung dvm new install

thanks for the replies, apologies for my absence, ive been on holiday for a week. rare, but these things have to be done in winter!

taz: yes the vac pumps were isolated, the vac guage would be off the scale otherwise!

i did away with the charging hoses for the latest vac and used 1/4" copper tube instead. the guage fittings are ok.

after more than an hour it does rise over 1000micron.

looking at brian's graph, it would suggest a leak.

sedgy: when i did all the piping i welded the them shut at each indoor unit and pressure tested and it held fine for 2 months.

then installed all the indoor heads and now under pressure test and vacuum there is a leak.

i dont think that is rushing, how else can it be done? the system cannot be vacced or pressure tested until every single indoor unit is connected.

my problem appears to be a leak on an indoor unit somewhere, but how to isolate the leak when there are 17 indoor units? thats my challenge. if i could isolate certain 'branches' of the system it would be a lot easier, but this vrf stuff is just one giant monster!

ps. its interesting to note you guys suggest 2000microns after 1hr is still a tight system.