Results 1 to 22 of 22

Thread: Moisture in system

-

26-04-2009, 10:50 AM #1

Moisture in system

Hi all, this is a follow up to a system i have recently been trying to sort out.

The system is a Daikin 3MXS52E Multisplit. With three internal units. The pipes were pre-installed and was suspected to have moisture in the system.

I re-claimed all the gas from the system and performed a triple vac and break with ofn each time.

Having weighed the correct ammount of R410A back into system, i ran the system for approx 30 min without no problem on heating and then on cooling.

Now when i went to put back onto heating the exterior unit ran but the three Electronic Expansion Devices never opened and i noticed that the 1/4 line off the EEV was icing up. But there was no fault mode.

Does this mean that the system still has moisture.

-

26-04-2009, 04:15 PM #2

Re: Moisture in system

Hi,

What you mean with: "a triple vac"? and "break with ofn each time"?

If I understood well the A.C. work well during 30 minutes including the reverse cycle (heating the interior), right?

After that the cooling and heating of the interior doesn't work, is that it?

Did you meant 3 EEV doesn't feed the LP side heat exchanger?...but in the first 30 minutes did work, right?

Does the 1/4" line is liquid HP (upstream) or after the valve liquid LP (downstream)?

You did meant that the EEV doesn't open electrically or open electrically but doesn't feed the evaporator?

Supposing that there is moist is it possible that the orifices of EEV be iced after a while (30 min.) and blocked the the flow of refrigerant.

Where point of the AC did you made the vacuum?

RegardsTo make progress is never good enough, I want to do better and better and better

-

26-04-2009, 05:00 PM #3

Re: Moisture in system

Hi Sandro,

I vacuumed the system three times and everytime i broke the vac with nitrogen.

I vacuumed the system from the service valves.

The system was running for 30 mins in heating and then cooling.

And when i switched the system to heating again the outdoor unit was running but the indoor units were not and then i noticed that the 1/4 line was freezing up between the EEV and the heat exchanger.

I am on the asumption that the EEV would have electrically opened but if the orifice of the EEV was blocked then that would stop the flow of refrigerant.

-

26-04-2009, 05:15 PM #4

Re: Moisture in system

daikin has a procedure were you have to open all valves manually. see yuor manual for wich switches to change for opening the valve's.

ice

-

26-04-2009, 05:25 PM #5

-

26-04-2009, 05:27 PM #6

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Moisture in system

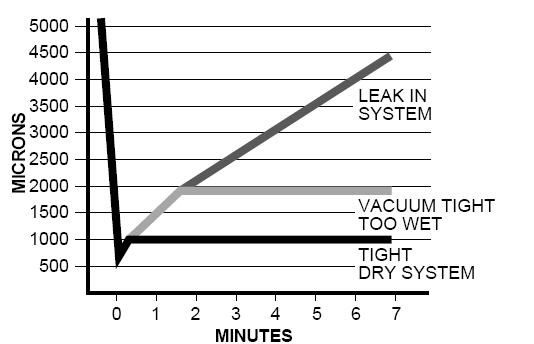

You did not posted what is your last reached vacuum and did vacuum held at between 500 and 1000 microns after about 10 min and more.

Triple evacuation without measuring vacuum is waste of time and doesn't mean that you now have dry and tight system.

Last edited by nike123; 26-04-2009 at 05:45 PM.

-

26-04-2009, 05:37 PM #7

Re: Moisture in system

if you are sure there was moistre in the system,it helps wen you warm the condensor or evap's during vacuming.warming up whit a hairdryer type blower.otherwise you blow up the sensors if the heat is to strong.

suc6, ice

-

26-04-2009, 05:49 PM #8

Re: Moisture in system

-

26-04-2009, 06:24 PM #9

Re: Moisture in system

its better and more acurate.

-

26-04-2009, 06:28 PM #10

Re: Moisture in system

by the way, if you suspect moistre in the system,you do the things you did before, vacuming and breaking whit Nē,but place filter-dryers just before the last vacuum. make sure they can be replaced after..say 1mond or so.

ice

-

26-04-2009, 06:38 PM #11

-

26-04-2009, 06:43 PM #12

-

26-04-2009, 06:45 PM #13

Re: Moisture in system

i wont do it like that,because of more moistre that can entering the system. keep it closed. put filter-dryers,give the system a vacuming of 24Hrs and start it up one at the time.if the first ones readings are good,start whit the nex one and so on.don't force anything yet.

if it works nearly normal,change the filter after one week. than again after 1mond. and than on year basis.

ice

-

26-04-2009, 09:42 PM #14

-

26-04-2009, 10:23 PM #15

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Moisture in system

It is relatively cheap tool, you could find satisfactory good product under 100 pounds.

http://www.thefind.com/query.php?que...c+vacuum+gauge

As instalation engineer you should have micron gauge, since you cannot properly made instalation (especially VRF/VRV system) without it.

Your customer should have record of instalation job with measured end vacuum data on it.

If you don't have micron gauge, how will you made that record.

If you did not done measurement during instalation (if you are made that instalation job), you did not installed system as procedure for instalation require, and you cannot fill commissioning report honestly, as required.

Last edited by nike123; 26-04-2009 at 11:02 PM.

-

27-04-2009, 09:30 AM #16

Re: Moisture in system

Quote:

Originally Posted by Sandro Baptista

Hi,

What you mean with: "a triple vac"? and "break with ofn each time"?

If I understood well the A.C. work well during 30 minutes including the reverse cycle (heating the interior), right?

After that the cooling and heating of the interior doesn't work, is that it?

Did you meant 3 EEV doesn't feed the LP side heat exchanger?...but in the first 30 minutes did work, right?

Does the 1/4" line is liquid HP (upstream) or after the valve liquid LP (downstream)?

You did meant that the EEV doesn't open electrically or open electrically but doesn't feed the evaporator?

Supposing that there is moist is it possible that the orifices of EEV be iced after a while (30 min.) and blocked the the flow of refrigerant.

Where point of the AC did you made the vacuum?

Regards

Hi Sandro,

I vacuumed the system three times and everytime i broke the vac with nitrogen.

I vacuumed the system from the service valves.

The system was running for 30 mins in heating and then cooling.

And when i switched the system to heating again the outdoor unit was running but the indoor units were not (Do you meant that is not "making" cool, cooling the air indoor?)

and then i noticed that the 1/4 line was freezing up between the EEV and the heat exchanger.

I am on the asumption that the EEV would have electrically opened but if the orifice of the EEV was blocked then that would stop the flow of refrigerant. And If the flow of refrigerant stops, or stop almost then the evaporators don't cool the air indoors.

Regards

To make progress is never good enough, I want to do better and better and better

-

27-04-2009, 10:52 AM #17

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

-

27-04-2009, 06:56 PM #18

Re: Moisture in system

Yo Mark & Nike123,

these days i can understand the use of a digital micron vacuum meter/divice, but was is done in the old days,i mean 15 to 20 years ago??? whit no digital hanky panky stuff. best whe teach first how and then refer to the best of tools,...no???

ice

-

27-04-2009, 07:02 PM #19

Re: Moisture in system

But we are not 15-20 years ago, we are living in the here and now with these tools available, so why not use them

The difference between genius and stupidity is that genius has its limits.

The difference between genius and stupidity is that genius has its limits.

Marc

-

27-04-2009, 08:31 PM #20

Re: Moisture in system

Re: Moisture in system

Hi Marc i used a torr gauge on the final vac which is much cheaper then a micron gauge.

Lets face it chaps working for a company is better because you donīt pay for expensive fridge tools.

Where as i do not and have to support a family so i have to work on time gone by as Icecube had pointed out.

-

27-04-2009, 09:03 PM #21

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Moisture in system

If you used Torr gauge, you actually measured vacuum, not that precise as with micron gauge but still 100 times more resolution than with you refrigerant gauge.

Until4 years ago, I used 0-1000 millibar (120 mm diameter) gauge. I still using it when I am on job which need long evacuation to see speed of progress until electronic vacuum gauge takes over.

But what is the point of triple evacuation if your hoses leaks, bad vacuum pump, bad oil, high moisture content or something else permit to reach satisfactory level and you don't have any mean to see that your goal is not achieved with that triple evacuation.

You could end up with system in same shape as before evacuation and not knowing that that is the case.

Wasted money and time (and time is money, if you have something else to do), polluted refrigerant, damaged system, etc... all because one control instrument which will always pay itself in few (if not in single one) job just because you don't need to pump more than it is necessary. We all know our safety factors from times when we are evacuated our systems without our vacuum gauges.

Last edited by nike123; 27-04-2009 at 09:09 PM.

-

27-04-2009, 09:13 PM #22

Similar Threads

-

Troubleshooting for Daikin Aircon CTK25FVEN

By JCTK in forum Air ConditioningReplies: 19Last Post: 05-06-2010, 07:18 PM -

CARE refigerants by BOC

By dogma in forum RefrigerantsReplies: 8Last Post: 23-03-2010, 12:39 PM -

How an expansion tank works?

By Raadster in forum FundamentalsReplies: 6Last Post: 25-07-2008, 02:25 PM -

dakin e3 code

By coolflow in forum Air ConditioningReplies: 2Last Post: 19-07-2008, 09:24 AM -

Automotive A/C Vent Temp Range vs System

By Don Browney in forum Air ConditioningReplies: 1Last Post: 15-05-2002, 06:19 AM