Results 1 to 24 of 24

Thread: Broken antivibration pipe

-

29-01-2009, 07:45 PM #1

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Broken antivibration pipe

I have one case where on compressor discharge has mounted anti vibration pipe which has leaked refrigerant out after only few days of operation.

Only data on pipe is HTH 37-08.

Does anyone know who is manufacturer of these anti vibrators.

What is correct term for them to search for manufacturers and their technical details? I forgotten English term for them. I think that we here use term "vibroflex"

Used refrigerant here is R410A and I fear that used anti vibrator is not strong enough for R410A pressures.

Unit is new one on the market. It is Galletti air to water heat pump MPE 028HO which is their first medium size system at R410A refrigerant.

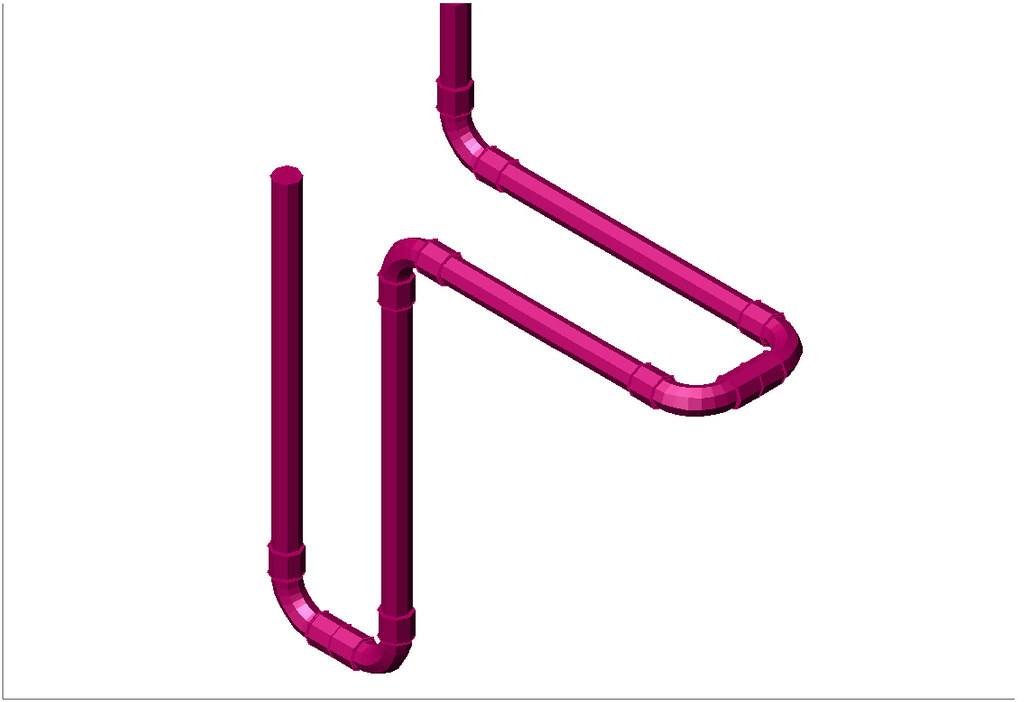

Here is partial picture of anti vibration pipe.

Last edited by nike123; 29-01-2009 at 08:43 PM.

-

29-01-2009, 08:17 PM #2

Re: Broken antivibration pipe

Hi Nike,

I just copied this form a catalogue I have. Down here we just call them vibration eliminators. The burst pressure is 500 psi on the one's I use.

VIBRATION ELIMINATORS

PIERCING & LINE TAP VALVES

SUITABLE FOR ALL HFC/HCFC/CFC REFRIGERANTS (Not ammonia)Maximum Test Pressure: 1-1/2 times Operating Pressure shown above.• High temperature alloys

Minimum Burst Pressure: 5 times Operating Pressure shown above.

• Vibration eliminators are used in the suction and discharge lines of refrigeration and air conditioning systems.

• They are most effective when installed as close as possible to the compressor, preferably in a horizontal position (but

not essential), with the refrigerant line anchored at the furthest end from the source of vibration.

• Care should be taken to ensure that the vibration eliminator is not under static tension after soldering in place. They are

not designed to compensate for lines that are out of alignment, so make sure lines are straight and in in line.

Hope this helps.

dsp

Last edited by Brian_UK; 29-01-2009 at 08:59 PM. Reason: Font size increased.

-

29-01-2009, 09:34 PM #3

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

-

29-01-2009, 09:37 PM #4

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Broken antivibration pipe

Does anyone have any names of vibration eliminators manufacturers in Italy or in EU?

I found:

Carly

http://www.vibrasorbers.com/

These Chinese is only 35 bar rated (500psig):

http://cntw.en.alibaba.com/product/2..._absorber.html

These are only 28 bars rated (fi 22)

http://www.amnitec.nl/UserFiles/File/Vibes.pdfLast edited by nike123; 29-01-2009 at 09:57 PM.

-

30-01-2009, 03:47 AM #5

Re: Broken antivibration pipe

Hi Nike I always used Anaconda

http://www.universalmetalhose.com/pr..._vibration.htm

Regards Norm

Sorry I posted the same post twiceLast edited by Toosh; 30-01-2009 at 03:54 AM. Reason: addition

My wife used to say you never listen to a word I say at least I think that what she said

-

30-01-2009, 07:42 AM #6

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

-

30-01-2009, 07:57 AM #7

Re: Broken antivibration pipe

Hi Nike, I have found anaconda failure in stressed piping, meaning the pipe has been been cut to short and pulled into fit which creates stress, and most products are usually have a failure point well above the operating pressure

NormMy wife used to say you never listen to a word I say at least I think that what she said

-

30-01-2009, 04:37 PM #8

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

-

30-01-2009, 05:08 PM #9

Re: Broken antivibration pipe

You might try some suppliers of hydraulic hoses and fittings. The pressures and fluids they work with could provide a reasonable option for you.

If all else fails, ask for help.

-

30-01-2009, 05:22 PM #10

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

-

30-01-2009, 08:19 PM #11

Re: Broken antivibration pipe

nike

do you have the space to replace the anti vibration pipe with a small coil shaped piece copper piper? i have had this problem on an old airdale package and made up a loop the loop arrangement of 5/8th and fitted that in its place,ok it it would not win a beauty pageant but it has done the jobPaul

"KEEP IT COOL"

-

31-01-2009, 12:58 AM #12

Re: Broken antivibration pipe

If the tubing is small enough for you to bend it into multiple loops, that might be OK. One thing to remember though... If the loop is vertical, it can trap oil or other in it during shutdown. If the loop is horizontal you can arrange it so the loop drains freely.

I have used some of the hydraulic hoses and connectors before and had good luck with them.If all else fails, ask for help.

-

31-01-2009, 11:37 AM #13

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Broken antivibration pipe

I think that 3 U turns in different planes and arm of pipes in length of 30-40cm will be sufficient.

This should be the shape but without elbows ( pipe would be from one piece and bended in this shape).

It is small scroll of 25 kW of refrigeration power and not much vibrations from what I seen first few days.

Maybe cause of vibration eliminator failing was fact that few days before failing unit was out of level some 3-5° because of unit anti vibration foots are fall out on one side of unit.Last edited by nike123; 31-01-2009 at 12:23 PM.

-

31-01-2009, 12:11 PM #14

Re: Broken antivibration pipe

I think the pressure rating of vibration eliminators drops as the size increases. What size pipe is it used with?

Jon

-

31-01-2009, 12:24 PM #15

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

-

31-01-2009, 01:17 PM #16

Re: Broken antivibration pipe

Follow US iceman post,

I only use SS vibration eliminators from the hydraulic sector, they are made up to 400 Bar.

On the other hand, Why use VE on hermetic compressor?

-

31-01-2009, 01:45 PM #17

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Broken antivibration pipe

I think it is too expensive and complicated to fit if there is no brazing connections at them. I also don't know where to find them here. Could you point me to some page where i could find more technical details and connection options?

It appears that someone in construction department of this unit thinking that they are necessary. Although, they are not fitted at suction side.On the other hand, Why use VE on hermetic compressor?

-

31-01-2009, 03:40 PM #18

Re: Broken antivibration pipe

Most of the energy for vibration is in the discharge lines, so that makes sense if you want to prevent the vibration (or noise) from traveling.

3 changes in direction for the loops is typical of expansion loops for increased flexibility to prevent pipe rupture or failure due to temperature related growth or shrinking of pipes. However, I do not think this will do very much for reducing vibration.

The issue with vibration is; trying to prevent the mechanical vibrations from creating mechanical failures or transmitting noise.If all else fails, ask for help.

-

31-01-2009, 08:29 PM #19

Re: Broken antivibration pipe

Hi Nike,

I will try to get you some pictures of these VE soon.

About hermetic compressors, they are equipped with internal springs to absorb any vibrations. If you get any, check for broken valves.

Don't forget that hermetics turn RPM .

you can try to change the RST to TRS, keep the same rotation direction and some times it reduces the vibrations.

-

31-01-2009, 08:45 PM #20

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

-

31-01-2009, 08:55 PM #21

- Join Date

- Sep 2007

- Location

- Split Croatia

- Age

- 57

- Posts

- 6,151

- Blog Entries

- 6

- Rep Power

- 36

Re: Broken antivibration pipe

When I was examining at initial start up of unit, I did not found that compressor makes any excessive vibrations or that vibration eliminator moves at all. In fact I found work of this compressor pretty smooth and quiet in comparison with earlier versions of Performers for R407C.

-

31-01-2009, 09:04 PM #22

Re: Broken antivibration pipe

-

31-01-2009, 09:34 PM #23

Re: Broken antivibration pipe

The Henry 7/8" 22mm vibration eliminators in my catalogue are rated at 34.5 bar, don't know what make yours was though.

-

10-01-2011, 06:40 PM #24

Re: Broken antivibration pipe

hi all the correct metod of using anaconda,s is that they are used in pairs= one vertical and one horizontal close together so that all the movement is taken by the anaconda,

of corce the pipework must be fasened = no movement .

sedgy

Similar Threads

-

Superheat and Subcooling

By Chunk in forum FundamentalsReplies: 42Last Post: 15-01-2011, 01:24 AM -

BS Box - 3 Pipe & 2 Pipe Systems.

By Testech in forum FundamentalsReplies: 2Last Post: 05-10-2008, 07:01 PM -

Burst Pipe caused by Abrasion. (aka Only on a Friday)

By Grizzly in forum Chit Chat & Service StoriesReplies: 11Last Post: 19-09-2008, 06:59 PM -

Mitsubishi PUHZ-RP200YHA Pipe Sizes

By gwilliamson in forum Air ConditioningReplies: 11Last Post: 14-05-2008, 09:43 PM -

Pipe sizes

By benncool in forum Chit Chat & Service StoriesReplies: 10Last Post: 08-07-2003, 10:58 PM